ADVANCED COMPRESSOR STRIP DOWN AND REBUILD COURSE – 5 DAYS

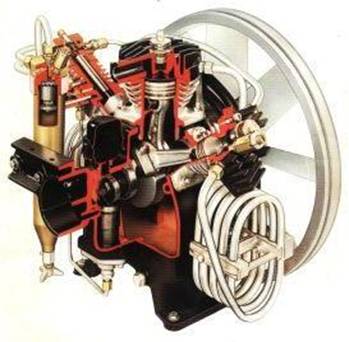

Examples of compressors types used during this Compressor training course:-

Examples of compressors types used during this Compressor training course:-Bauer Mariner 200 250 Bauer Capitano 140 Bauer Junior 100E, Bauer K-KAP Series, Coltrisub MCH6, Coltrisub MCH16, L&W Lenhardt & Wagner LW450ES *

Learn how to use and carry out routine servicing of all models… Then strip down, recondition & rebuild one*

A new course introduced by popular demand to extend the capabilities of compressor operators who have already completed the Compressed Air Systems Management Course, and for Specialist Dive Industry personnel with responsibilities for the advanced strip down and rebuild repair of high pressure divers breathing air compressors.

The course general maintenance, operation, standards and relevant legislation across all major manufacturers products and the following specific topics.

Compressor Academic Development Work (day 1)

- Legal requirements & regulations

- Operator Instructions

- Air facts and pumping rates

- Single stage compression – disadvantages

- Multi stage compression

- Compressor Efficiency

- Determining Compressor size requirements

- 3 stage High Pressure compressor – essential system parts.

- Water separator & filtration system

- Filter composition – chemicals used

- Air Quality Measurements – EN12021

- Air Quality test Methods

- Lubrication methods and oil types

- Explosion hazards,

- Compressor use – essential operator tasks

- Compressor use – essential maintenance tasks

- Air bank usage

- V-belt adjustment

- Pulley wheel alignment

- 3 phase electricity supply fundamentals

- 3-phase Star-Delta Starter fundamentals

- 3-phase motor protection systems

- Advanced EN12021 Breathing Air Filtration System Design & PMV Dependency

- Water content of air at different temperatures

- Predicting Molecular sieve lifetime

- Predicting Activated Carbon lifetime

- Hopcalite requirements for carbon monoxide filtering

- Compressor and air storage systems horror stories, photo examples.

- Compressor Servicing Manuals usage

- Spare parts ordering

- Manufacturers product reviews

- THEORY EXAM

Workshop Session (day 2)

- Hands on user servicing and run up tests of (all models)

- Bauer Junior, Bauer Capitano, Bauer Mariner, K14

- Coltrisub MCH6, Coltrisub MCH16

- Workshop Session Days(3,4,5)

* Chose from either:- Bauer Junior, Bauer Capitano, Bauer Mariner, Coltrisub MCH6, Coltrisub MCH16

- Remove and replace protective guards

- Remove and replace intercooler pipes

- Remove and replace cylinder heads

- Remove and replace cylinder barrels

- Examine cylinder barrels for wear

- Examine bearings for wear.

- Strip down and adjust safety valves

- Strip down and rebuild final Bauer p21 safety valve

- Strip down and adjust PMV

- Strip down and service Interstage condensate trap replace filter

- Strip down and repack P21 filter

- Adjust high pressure Oil Pump setting of Bauer final stage lubrication system.

- Setup and use of Bauer B-timer Automatic filter monitor

- Use of interstage pressure gauges for fault finding.

- Test compressor to 330bars to confirm integrity and lack of leaks

- Power consumption measurement – use of Voltmeter & clip on ammeter.

- Rpm measurement methods

- Heat measurement of heads and intercooler functionality checks

- 3-phase wiring basics – Changing rotation direction of 3-phase electric motor

- 3-phase star-delta starter / 6 wire 3-phase motor basics. Adjusting Star-delta switch time.

- Petrol engine rpm regulator adjustment for correct rpm

- Alignment of drive motor and fan belt adjustment

- Pumping efficiency tests

- Compressor Log sheets use

- Introduction of faults to the compressor and technician booby traps

- EN12021 Air purity testing – preparation and test workshop following rebuild

Includes:

- ASSET/IDEST approved Compressed Air Systems Maintenance Certification establishing the legal competent person status of the technician to work on all compressed air systems

- All student training Manuals used during the course + online access to the ScubaEngineer.com technician database

- All compressor spare parts & consumables used during the course

- Free Tea/Coffee and high speed Wi-Fi internet access at the training center

- There are no formal pre requisites for this course.

Key Benefits

- Prevents costly damage to the compressor unit through lack of operator care

- Prevents costly damage or destruction of the dive centers scuba tanks through the moistures damage resulting from the damp air supplied from an incorrectly cared for compressor

- Provides proof of formal compressor and air bank training. When a new compressor stops working, manufacturers often blame the operator or the owner if the person responsible for compressor operation has no training. If the compressor operator has formal training, the blame for compressor failure shifts to the manufacturer or supplier of the unit.

* Exact compressor models used for training may vary as older units are retired and newer units are brought into the technician training workshop.

Training Center Information

EASYTEK ENGINEERING SERVICES CO LTD – an A.S.S.E.T., IDEST & SITA Approved Training Provider

Capabilities of Easytek Engineering Services Co Ltd., as an Engineering Training Provider

Easytek Engineering Services Co Ltd., together with STATS in the United Kingdom have provided a unique service to Commercial Diving Companies, Military Diving Teams, Government Inspectors, Recreational Dive Centres, SCBA, ELSA, HEED Life Support Technicians, High Pressure Cylinder Inspectors, and other Dive Industry Professionals internationally for more than 20 years drawing on the wide experience of its principal staff. Principle capabilities include:

- Divers and other SCBA life support equipment maintenance – regulators, compressors, cylinders, rebreathers, hydrostatic test equipment design, NDT analysis

- Commercial diving, & Maritime consultancy. Dive incident investigation & expert witness testimony

- Custom Decompression methodology for 1,000ft Trimix diving.

- Approved engineering training. International recognised certification in Trimix Decompression diving, sunken vessel survey, underwater artifact & body recovery.

- Repair, servicing & testing traceable to National standards. Design, Manufacture and sales of custom tools, adapters and test equipment for Divers life support equipment servicing and other critical high pressure applications.

Easytek has the most modern divers life support equipment service center and mixed gas production system in Thailand. All mixed gases can be pumped to 350bar via in house Haskell booster pumps powered by twin Bauer Compressors feeding a 90,000Liter air bank. Easytek carries out hydrostatic tests in house to 650bar/10,000psi to US DOT standards, European EC, British BS and Thai standards supplemented by the very latest NDT eddy current testing to detect metallurgical failure aluminium alloy high pressure gas cylinders.

For further information or to book a course please contact us