Providing the Dive Technician Training , scuba regulator spare parts and parts diagrams supporting the work of more than 1,500 Dive Technicians World Wide

Servicing Scuba Equipment: An introduction

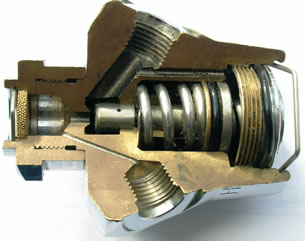

All equipment used by divers underwater or for the provision of their breathing gases is fundamentally life support equipment. Scuba regulators, scuba tanks and compressors work at extremely high pressures and use innovative engineering design techniques to function correctly.

The service and repair of scuba equipment is not intuitive even for those with formal engineering training in other disciplines. Scuba regulator spare parts kits and scuba repair tools are also difficult source and purchase.

Only formal training in the repair and maintenance of dive equipment such as that received during the ASSET approved Dive Industry Technicians Course (DITC) can ensure the continuing safe and reliable operation of life support equipment.

Servicing SCUBA regulators

Only technicians who have attended recognised training should attempt to service a scuba regulator. Many diver deaths have been caused by amateur attempts of scuba regulator repair.

Additionally, original manufacturer scuba regulator spare parts, custom tools, parts diagrams solvents and greases must be used.

All technical support from this web site is only made available formally trained service technicians.

Industry brand leaders such as Scubapro, Oceanic, Aqualung, Apeks, Mares, Poseidon, care about the safe reliable performance of their products. All brand leaders set up extensive international networks of service centers with formally trained technicians to accomplish this task.

The Dive Industry Technician Training Course or DITC is the only approved training available to provide broad based ‘hands-on’ experience in servicing regulators from all the worlds major manufacturers of dive equipment. All DITC graduates are granted username/password aces to a comprehensive online database covering more than 200 manufacturers technical servicing standards.

Experienced, formally qualified Divers Life Support Equipment technicians holding manufacturer training certificates may also apply for a Username & password to their specific manufacturers tech data held online by Contacting ScubaEngineer.com

Inspecting Scuba tanks

The standard American DOT 3AL-3000 aluminium scuba tank is an amazing piece of metallurgical technology. The single piece non-welded cylinder, plus heat treatments results in strength many times that of the pure aluminium.

Rough handling, corrosion, heat and many other factors can critically effect the strength and integrity of its construction. The end result is an explosion, that usually occurs during refilling, killing the compressor operator and destroying the dive center.

Inspection of scuba tanks is a hazardous activity. Technicians have had limbs amputated when trying to remove the valve from pressurized cylinders.

Cylinder Inspection Incident on Koh Tao

A dive instructor working at Koh Tao, Thailand suffered a critical injury when a scuba tank valve exploded. The pillar valve plus the removal tool was jettisoned through his leg during a servicing action. The aluminium tank rocketed at great speed through few several concrete walls before landing in a tourist’s bungalow. Thankfully no one else was injured. A well trained Israeli army medic hanging around nearby applied a tourniquet on the injured guy’s leg saving his life.

Millions of scuba tanks still in use are made of an obsolete aluminum alloy that suffer from Sustained Load Cracking. Cracks develop in the neck region that eventually causes the cylinder to explode. These older cylinders must be tested using NDT equipment. New Zealand recently banned cylinders made from this older T6351 aluminum alloy – other countries are expected to follow suit soon.

Steel scuba tanks – are they safer than aluminium?

Since ‘rust never sleeps’ steel tanks have their own problems when used in a marine environment. In one example, a flooded steel cylinder exploded within just a few months.

Corrosion can also use up the oxygen level in the tank causing death through hypoxia. A flooded steel scuba tank lying suffers accelerated corrosion caused by the high pressure of air in the tank. This leads to critical weakening of the cylinder wall sufficient to cause an explosion.

Comprehensive training in Scuba tank inspection such as the ASSET approved courses below, saves lives.

- Cylinder Testing Course – Pt 1 (Practices and Procedures)

- Cylinder Testing Course – Pt 2 (Metallurgy, Inspection and Determination)

- Composite Cylinder Inspection Training Pt3

![]() Includes a full revision of both US-DOT, European, Australian and British Inspection standards

Includes a full revision of both US-DOT, European, Australian and British Inspection standards

Using Compressors and Air Banks

High Pressure Air Compressors look simple to repair like a motorbike engine. However, high pressure engineering is a very specialist field with many unique safety hazards. When a compressor fails, it can explode killing the operator and even sink the dive boat. A major issue is that a sick compressor pumps moist air into the dive shops scuba tanks causing internal corrosion. Replacing dozens of corroded scuba tanks that fail inspection will cost thousands of dollars.

Compressor spare parts

Use original manufacturer parts for all repairs. The use of fake spares or filling hoses can easily lead to the death of the compressor operator

The safe use of Oxygen/Nitrox/Trimix blending systems can only be achieved through training of all key personnel involved. A trained compressor operator changes filter cartridges on time saving money replacing internally corroded scuba tanks.

- Compressed Air Systems Management Course CASM

- Advanced Compressor Strip down rebuild course ACASM

- Oxygen Service Technician & Nitrox/Trimix/Heliox Gas Blending Course

Dive Industry Technician Training – a brief introductions

More than 1,500 DITC technician students support scuba, commercial and military diving worldwide.

Emphasis on servicing procedures in accordance with original manufacturer technician workshop standards.

Post training consultancy and multi-manufacturer tech support for all our training course graduates is provided online at www.ScubaSpareParts.com and by experienced divers life support equipment experts Mr Stewart Meinert & Stephen Burton C.Eng.,

Click here for more information on how to become a Dive Technician.